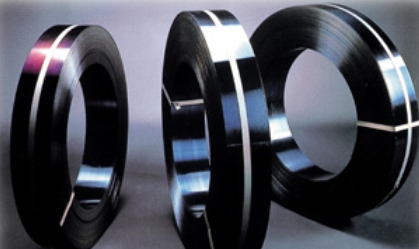

MOLITEC STEEL has been handling heat-treated steel strips for half a century and created HIGH-BENT and big-breadth heat-treated steel strips with technologies developed after years of study, and have been making many contributions to all the industries with its world’s top brand products.

HARENED & TEMPERED STEEL STRIPS

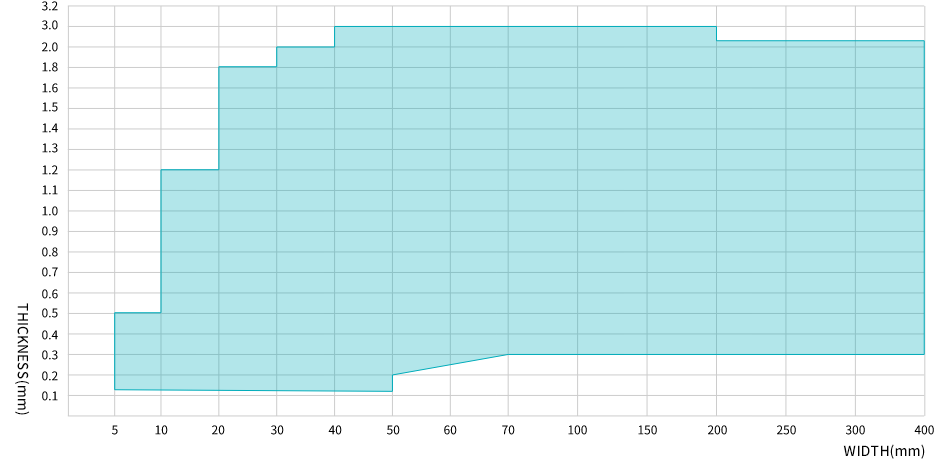

MOLITEC STEEL processes carefully selected materials such as cold-rolled special steel strips, stainless steel strips, etc. by continuous heat treatment, etc. and produces heat-treated steel strips suited for various applications under the stringent quality control system. In particular, big-breadth heat-treated steel strips 400 mm (16″) wider achieve the stable profile with our original techniques and enjoy great popularity among many users.

TYPICAL APPLICATIONS

-

AUTOMOBILE •

CLUTCH PARTS -

BLADES & SAWS

-

POWER SPRINGS

-

OTHER PRESSED PARTS

SURFACE FINISH

| SURFACE APPEARANCE | DEFINITION |

|---|---|

| Standard (Unpolished Black, Unpolished Blue, Unpolished Straw) |

Hardened and tempered natural colour without colouring process of which oxidised surface colour is decided on hardness required. |

| Unpolished Semi Bright | Hardened and tempered non-oxidised where semi bright surface is required on requested hardness. |

| Polished Bright | Polished after hardening and tempering. |

| Polished Blue | Colouring in blue after polishing. |

EDGE FINISH

| SORT OF EDGE FINISH | CROSS SECTION | DEFINITION | APPLICATIONS |

|---|---|---|---|

| Slit edges |

|

Sharp edges with slitting burrs left on | Washers |

| Deburred edges |

|

Edges removed at burrs from slitting | Leaf springs |

| Round edges |

|

Rounded after slitting | Power springs |

| Square edges |

|

Squared after slitting | Saws, Blades, Band saws |

AVAILABLE DIMENTIONS

THICKNESS TOLERANCE

| THICKNESS | THICKNESS TOLERANCE | ||||

|---|---|---|---|---|---|

| STANDARD | SPECIAL | ||||

| A | S | SS | |||

| 0.15min. 0.25excl. (0.0059min. 0.0098excl.) |

±0.015 (±0.00059) |

±0.010 (±0.00039) |

±0.008 (±0.00031) |

||

| 0.25min. 0.40excl. (0.0098min. 0.0157excl.) |

±0.020 (±0.00079) |

±0.015 (±0.00059) |

±0.010 (±0.00039) |

||

| 0.40min. 0.60excl. (0.0157min. 0.0236excl.) |

±0.025 (±0.00098) |

±0.020 (±0.00079) |

±0.015 (±0.00059) |

||

| 0.60min. 0.90excl. (0.0236min. 0.0354excl.) |

±0.030 (±0.00118) |

±0.025 (±0.00098) |

±0.020 (±0.00079) |

||

| 0.90min. 1.20excl. (0.0039min. 0.0059excl.) |

±0.040 (±0.00157) |

±0.030 (±0.00118) |

±0.025 (±0.00098) |

||

| 1.20min. 1.60excl. (0.0472min. 0.0630excl.) |

±0.050 (±0.00197) |

±0.040 (±0.00157) |

±0.030 (±0.00118) |

||

| 1.60min. 2.10excl. (0.0630min. 0.0827excl.) |

±0.055 (±0.00216) |

±0.050 (±0.00197) |

±0.040 (±0.00157) |

||

| 2.10min. 2.60excl. (0.0827min. 0.1024excl.) |

±0.060 (±0.00236) |

±0.055 (±0.00216) |

±0.050 (±0.00197) |

||

| 2.60min. 3.20excl. (0.1024min. 0.1260excl.) |

±0.065 (±0.00256) |

±0.060 (±0.00236) |

±0.050 (±0.00197) |

||

The Location of thickness measurement shall be at any arbitrary point more than 10mm (0.3937″) away from either edge, or the centre of the width if the strip does not exceed 20mm (0.7874″).

WIDTH TOLERANCE

| THICKNESS | WIDTH TOLERANCE | ||||

|---|---|---|---|---|---|

| 50excl. (1.9685excl.) |

50min.- 100excl. (1.9685min. -3.9370excl.) |

100min.- 200excl. (3.9370min.-7.8740excl.) |

200min.- 300excl. (7.8740min.-11.8110excl.) |

300min.- 400max. (11.8110min.-15.7480max.) |

|

| 0.30excl. (0.0118excl.) |

±0.30 (±0.01181) |

±0.35 (±0.01378) |

― | ― | ― |

| 0.30min. 0.60excl. (0.0118min. 0.0236excl.) |

±0.20 (±0.00787) |

±0.30 (±0.01181) |

±0.50 (±0.01969) |

±0.80 (±0.03150) |

±1.00 (±0.03937) |

| 0.60min. 1.20excl. (0.0236min. 0.0472excl.) |

±0.20 (±0.00787) |

±0.25 (±0.00984) |

±0.50 (±0.01969) |

±0.80 (±0.03150) |

±1.00 (±0.03937) |

| 1.20min. 1.60excl. (0.0472min. 0.0630excl.) |

±0.20 (±0.00787) |

±0.25 (±0.00984) |

±0.50 (±0.01969) |

±0.80 (±0.03150) |

±1.00 (±0.03937) |

| 1.60min. (0.0630min.) |

±0.20 (±0.00787) |

±0.25 (±0.00984) |

±0.50 (±0.01969) |

±0.80 (±0.03150) |

±1.00 (±0.03937) |

EDGE CAMBER TOLERANCE

AT 2m (6.5FEET) OPTIONAL POINTS

(単位:mm)| WIDTH | TOLERANCE |

|---|---|

| 25excl. (0.984excl.) |

4.0 (0.157) |

| 25min. 60excl. (0.984min. 2.362excl.) |

4.0 (0.157) |

| 60min. 100excl. (2.362min. 3.937excl.) |

8.0 (0.315) |

| 100min. (3.937min.) |

8.0 (0.315) |

FLATNESS TOLERANCE

THE FLATNESS TOLERANCE OF A CUT SHEARED FROM A STRIP IS INDICATED BELOW.

UNIT:mm(inch)| WIDTH THICKNESS |

TOLERANCE | |||||

|---|---|---|---|---|---|---|

| 30min.- 50excl. (1.18min.-2.36excl.) |

50min.- 100excl. (2.36min.-3.94excl.) |

100min.- 150excl. (3.94min.-5.91excl.) |

150min.- 250excl. (5.91min.-9.84excl.) |

250min.- 350excl. (9.84min.-13.78excl.) |

350min.- 450max. (13.78min.-15.75max.) |

|

| 0.20excl. (0.0079excl.) |

0.20 (0.0079) |

0.30 (0.0118) |

― | ― | ― | ― |

| 0.20min. 0.40excl. (0.0079min. 0.0157excl.) |

0.15 (0.0059) |

0.30 (0.0118) |

0.30 (0.0118) |

0.30 (0.0118) |

0.40 (0.0157) |

0.45 (0.0177) |

| 0.40min. 0.80excl. (0.0157min. 0.0315excl.) |

0.15 (0.0059) |

0.20 (0.0079) |

0.25 (0.0098) |

0.30 (0.0118) |

0.40 (0.0157) |

0.45 (0.0177) |

| 0.80min. 1.20excl. (0.0315min. 0.0472excl.) |

0.15 (0.0059) |

0.20 (0.0079) |

0.25 (0.0098) |

0.30 (0.0118) |

0.40 (0.0157) |

0.45 (0.0177) |

| 1.2min. (0.0472min.) |

0.15 (0.0059) |

0.20 (0.0079) |

0.25 (0.0098) |

0.30 (0.0118) |

0.40 (0.0157) |

0.45 (0.0177) |